Source: Market Prospect

The machines used in the textile industry exhibit a wide range of diversity, each serving distinct purposes. The transformation of fibre into fabric entails a lengthy and time-consuming process.

It’s unsurprising that certain fabrics command high prices due to the utilization of advanced technology in the machinery, ensuring excellent fabric quality. Each stage of the process significantly influences the final cloth result, encompassing factors such as density, thickness, and color patterns, with the spinning process playing a pivotal role.

In this article, we will learn about the comprehensive exploration of the machines used in the textile industry and their respective functions.

Also Read: What’s Digital Printing on Fabrics? Types, Pros and Cons

List of Machines Used in the Textile Industry

Ever wondered about the intricate transformation of fibres into the garments we don daily? Crafting a piece of fabric involves a nuanced process aimed at producing top-quality textiles.

The behind-the-scenes workings of the textile industry often elude many. Now is your opportunity to unravel the intricacies and explore the array of machines used in the textile industry. Dive into the information below!

1. Yarn Twisting

Source: Saurer

Fabric production commences with the initial step of spinning. There is a machine in the textile industry called a thread twister is employed to aggregate threads into a large, unified coil. Typically, the spun threads maintain a single color, often white, streamlining subsequent processes.

The wound thread needs to be orderly and meet production standards. Tangled threads can significantly affect the quality of the fabric produced later on.

2. Knit Divisions

Source: Bintang Harapan Kurnia

Afterwards, the collection of skeins is assembled and woven together to create a fabric. Each fabric type undergoes a distinct process within this knitting phase.

Whether it’s jersey, spandex, cotton, or interlock fabric, specific machines cater to each type, and they cannot be interchanged. This stage is pivotal as it profoundly influences the final appearance of the fabric surface.

Also Read: 5 Fabric & Textile Trends in 2024, A Go-To Guide You Can’t Miss!

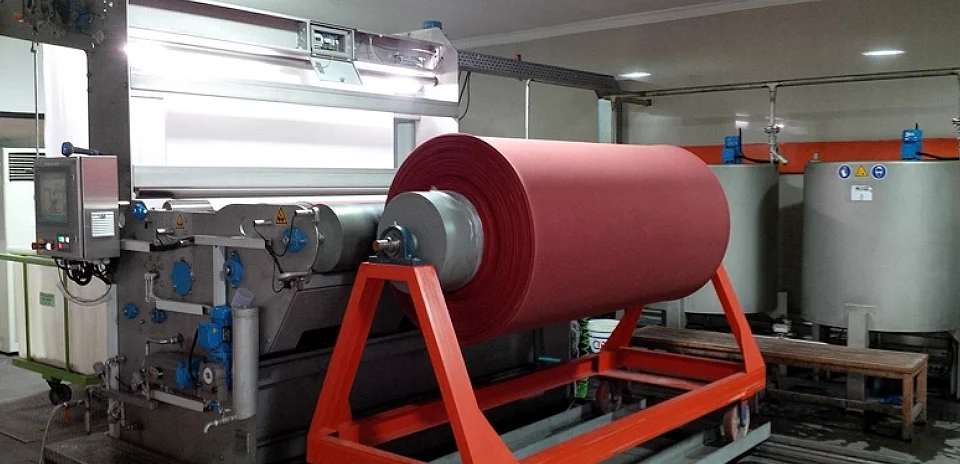

3. Pre-Treatment

Source: Bintang Harapan Kurnia

Before entering the pre-treatment phase, the fabric slated for the dyeing process must exhibit good quality to facilitate thorough color absorption into the fabric fibres. This ensures that the resulting color is uniform, dense, and of superior quality. The pre-treatment process typically commences with continuous scouring and advances through the bleaching range.

Scouring adalah proses untuk menghilangkan komponen penyusun seperti minyak, debu, wax, ataupun kotoran yang menempel pada serat kain. Kemudian disambung dengan proses bleaching yang bertujuan mengilangkan pigmen serat alami yang ada pada kain.

4. Singeing

Source: Bintang Harapan Kurnia

Singeing is the process of burning to eliminate fine fibres on the surface of the fabric. This is achieved by passing the fabric through a small flame or a heated copper plate, causing the fine fibers to instantly disappear. In the present modern era, this burning process is assisted by specialized machines, making the entire procedure much faster and more efficient.

5. Dyeing Divisions

Source: Bintang Harapan Kurnia

Dyeing is the transformative process of changing the basic color of fabric to a new, distinct hue. There are machines used in the textile industry known as dyeing divisions. These machines facilitate the intricate process, capable of executing multiple stages, including color formulation, fabric dyeing, re-dyeing, fabric washing, and drying. The result is a fabric ready to proceed to the subsequent stage.

6. Finishing

Source: Bintang Harapan Kurnia

Finishing marks the concluding phase in fabric preparation before it is ready for sale on the market. During this stage, numerous textile mills employ a stress-free drying process to minimize shrinkage. This involves a controlled drying process and a pre-heat setting method using a Stenter, which effectively secures the quality of the fabric.

These are the six processes and machines utilized in the textile industry that are essential to understand. If you’re seeking a one-stop shop offering a diverse range of fabrics for fashion, Bintang Kurnia Harapan is the answer!

Also Read: What’s The Difference Between Apparel and Clothing?

Bintang Harapan Kurnia proudly holds the title of Bali’s premier fabric store, loved by many customers for over two decades with its extensive fabric collection. Serving as a trusted partner for over 200+ fashion brands, Bintang Harapan Kurnia introduces a fresh fabric buying experience.

What makes Bintang Harapan Kurnia the leading fabric store in Bali? With decades of experience, the establishment has earned prestigious awards, such as the Sustainable Style Leadership Award, Luxury Textile Excellence Award, Couture Craftsmanship Distinction, and more.

Don’t hesitate any longer! Visit Bintang Kurnia Harapan now and discover your ideal fabric!